In this episode, we explore our next prototype design and review some of the scientific parameters associated with the prototypes. We also propose a challenging thought experiment.

Welcome back to Jets in Space.

Prototypes will be the lifeblood of this concept as we need to show thrust production in larger-scale models.

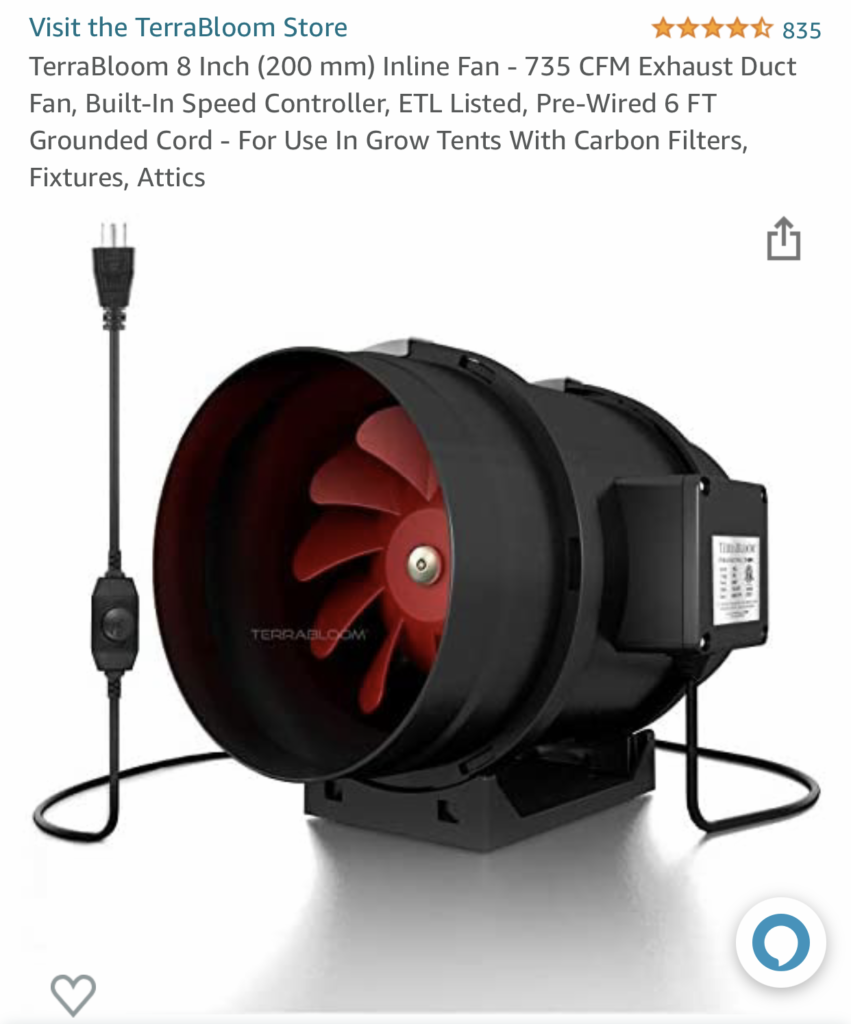

Phase 2 prototype currently under construction involves a ducted greenhouse fan (see our YouTube video). We might attach a ventilation duct to narrow the aperture of gas escape. We will use transparent plastic tarps spread over a metal wire frame to make the next-level airtight container. Hopefully, this will keep weight to a minimum.

Instead of using water surface to demonstrate thrust production. We will attempt a wheeled platform so that we can display the prototype without the need for a water surface. In the YouTube video, a skateboard is used in the demonstration.

I’d like to challenge your imagination with the following:

Consider in your mind that we have a Star Trek matter transportation system. We use this transporter to move an entire Boeing 777 airplane ✈️ into geostationary orbit several miles away from earth.

We take an engineering crew and remove the wings, landing gear, tail section, and all internal seating, essentially making the fuselage into a large hollow tube.

We then take both engines and mount both internally vertically (one on top of the other) at the foreword section nearest the cockpit.

For argument’s sake, we have also made the fuselage airtight. Also for argument’s sake, we have an electric motor to spin the turbofan blades and there is one atmosphere of normal earth like oxygen and nitrogen mixture within the fuselage.

Would that fuselage produce detectable motion from the internal thrust production? My hypothesis is that it would be able to move in a vectored fashion depending on its orientation and it’s thrust to weight ratio.

Consider on the surface of the earth, the same engines and fuselage were able to reach subsonic speeds. In the vacuum of space, we remove drag and minimize gravity. Speeds could be higher without these forces acting upon the fuselage.

The Turbofan: High Bypass Ratio. Just a reminder that modern airlines use turbofan engines due to high efficiency of the forward fan blades that operate like an internal propeller. High bypass meaning a significant amount of air is going around the combustion core and thereby not being subjected to chemical or caloric modifications.

Repurposing aircraft graveyard (Arizona)?

When airline craft pass their useful lifespan, they go to a special desert 🏜 graveyard in Arizona I believe. Thousands of old fuselages sit there and could be repurposed to create IAP drives? Airline fuselages are designed to hold relatively normal air pressures at high altitude, so we already have multiple air tight containers waiting to be used?

Potential energy of compressed gasses review from Episode 2.

One concept that will greatly influence prototype design is the potential energy of compressed gasses as mentioned in a previous episode. My hypothesis rests on thrust production from releasing compressed gasses in a controlled fashion and letting that compressed gas expand in the thrust generation corridor until it loses the majority of its potential energy. After that energy has been used for thrust generation, the relatively lower pressure gas is then “recycled” by the atmosphere return corridor to begin the process again continually.

Calculus of delta pressure over delta distance from source of pressure. PV=nRT. Would need pressure sensors throughout the apparatus.

2-3 versus Half atmosphere pressure gradients. One variable for future experiments would be to vary the resting pressure within the airtight container. The resting pressure being the pressure inside the airtight container without the fan blades spinning. Would thrust production be more efficient at half an atmosphere internally versus 2 atmosphere pressure. Most likely, higher resting internal pressure would mean a heavier airtight container to withstand the resting air pressure, so thrust to weight concerns would come into play again.

Sail Effect versus Weight Restrictions.

A person on Facebook commented that the air pushing on the back wall of the container would cancel out some of the thrust produced. That was an excellent question and observation and I termed this a “sail effect”. Just as a sail boat uses wind pushing on the fabric to generate motion, there would be some force pushing on the airtight container in the opposite direction of thrust in outer models. First, the surface area involved is small enough where I believe thrust production would overcome this phenomenon. Second, we could design a conical structure at the end of the thrust generation corridor that would theoretically minimize the sail effect by further reducing the surface area subject to this effect.

Phase 3 Prototype? I am currently in search for phase 3 prototype components. Luckily my phase 2 prototype engine came ready to use as an electric greenhouse fan. I’m open to ideas that can serve as future motors such as HVAC systems? Eventually, we will need to use turbofan blades similar to jet engines, but that prototype major funding and engineering support.

Notable Links

- Jets in Space Facebook Group

- Internal Atmospheric Propulsion IAP LinkedIn

- Internal Atmospheric Propulsion IAP Facebook

Podcast Production Services by EveryWord Media

Resources Mentioned:

Join us on Facebook!